BIM-models library – 2016

-

GOST R 56729-2015 (EN 14313:2009) establishes general rules for all manufacturers of foamed polyethylene insulation.

Details

Until June 2016, manufacturers themselves established technical requirements for manufactured insulation materials and received certificates for compliance with these requirements. As a result, it was not possible to objectively compare the characteristics of different materials. In such conditions, there was a need to create a national standard, one for all market participants. Therefore, with the participation of our company's specialists, GOST R 56729-2015 was developed and put into effect. It establishes general requirements for all manufactured materials from EPE.

For example: In accordance with GOST, all materials whose thermal conductivity exceeds 0,05 Вт/(m•°С) (at 10°С) are not insulation for engineering equipment of buildings and industrial installations.

-

Materials must tested according to the unified methods established by GOST.

Details

Before the advent of a single national standard, manufacturers of insulation materials could arbitrarily choose test methods. GOST introduced a unified methodology, thanks to which all market participants are put in the same conditions.

-

Technical characteristics must confirmed by certification test reports. Information on technical characteristics must posted on the product or its packaging.

Details

In accordance with GOST, the technical characteristics must be declared by the manufacturer and confirmed by certification tests. At the same time, declarations, test reports and certificates of conformity must be publicly available, and technical characteristics must be reflected in the labeling of the products or packaging themselves. The manufacturer's lack of such protocols and certificates may mean that the declared characteristics either do not correspond to the real ones, or have not been confirmed by tests at all.

-

In accordance with GOST, all products must undergo systematic tests to confirm the declared characteristics.

Details

Before the introduction of GOST, the frequency of testing was established by the manufacturers themselves. As a result, & ndash; tests may not have been conducted for decades. GOST sets clear deadlines for confirming each of the technical characteristics:

- dimensions and limit deviations & ndash; 1 every 24 hours;

- thermal conductivity & ndash; 1 every 2 years;

- maximum operating temperature & ndash; 1 every 5 years;

- water vapor diffusion resistance factor & ndash; 1 every 5 years;

- water absorption & ndash; 1 every 5 years.

- Revit 2019 project in «.rvt» format with insulation families;

- two «.dyn» files with scripts for Dynamo 2.0.

- name and type of insulation;

- standard size with thickness;

- name of regulatory document;

- article;

- quantity of material;

- manufacturer's trademark.

- perform automatic calculation of quantity of insulation, coating material and accessories;

- create a two-layers insulation structure or add a protective covering Energopack<® TK SK;

- take into account the consumption of insulation materials for fittings (shaped elements);

- set the required safety factor for insulation;

- search for errors in insulation sizes by element`s ID;

- fill the specification automatically.

-

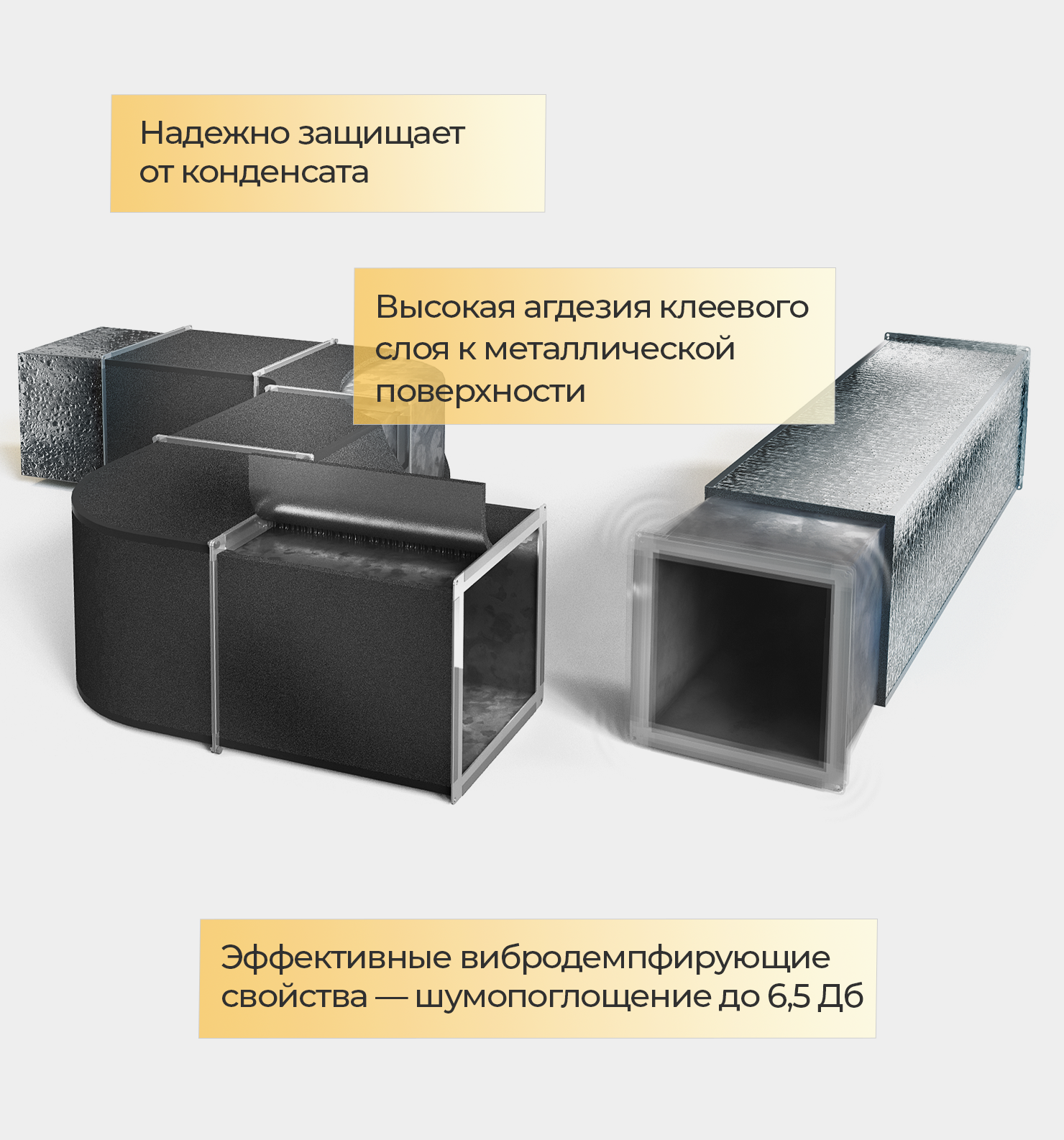

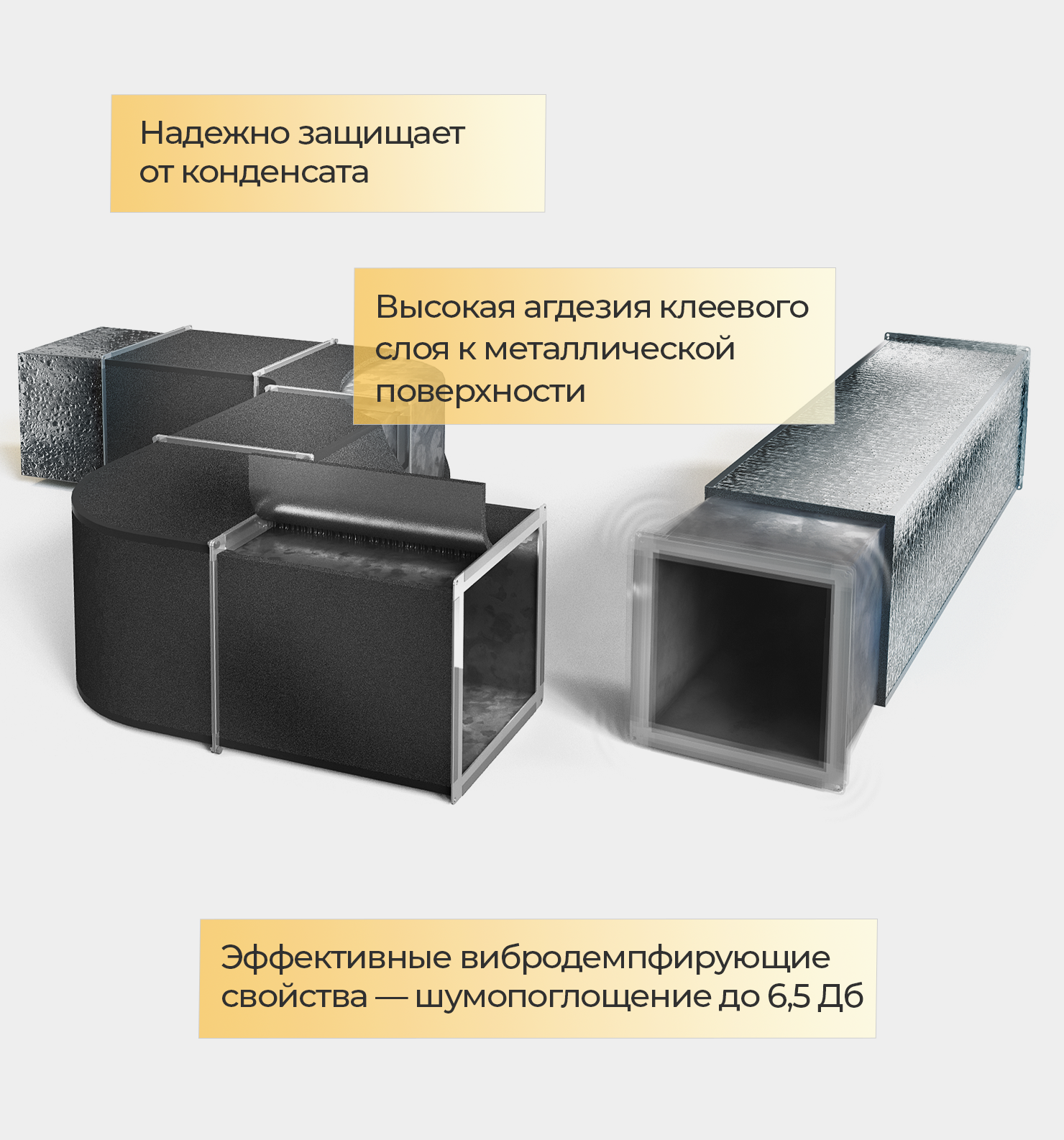

STO 59705109-012-2021 «Constructions of insulation for the equipment and pipelines with the use of Energomax® insulating products Energomax made of foamed polyolefin plastomer. Engineering and installation»Details

The standard is developed into account the requirements of SP 61.13330.2012. It establishes the requirements to design and perform installation works for insulation structures using insulation products Energomax made of foamed polyolefin plastomer. Energomax® products are intended for insulation of equipment, pipelines and air ducts of utility networks, ventilation and air conditioning systems, process systems with an insulated surface temperature from – 80 °С to + 105 °С. They are made of the latest polymer and combine the advantages of two of the most common thermal insulation materials:

- durability, strength, frost resistance and low smoke formation of polyethylene;

- flexibility of of flexible elastomeric foam.

Hide

-

STO 59705109-007-2014 «Designs of insulation for the equipment and pipelines with application of insulating products from flexible elastomeric foam (FEF) «Energocell® HT. Engineering and installation»Details

It is the Russia's first standard on design of insulating designs for the flexible elastomeric foam. It not only contains a list of the recommended thickness of a insulation layer from the products Energocell® HT in insulating designs, but also allows to provide at design:

– energy efficiency of designs of insulation;

– increase of level of safety of the operated engineering communications;

– improvements of operational properties and increase of durability of designs of insulation.

Hide

-

-

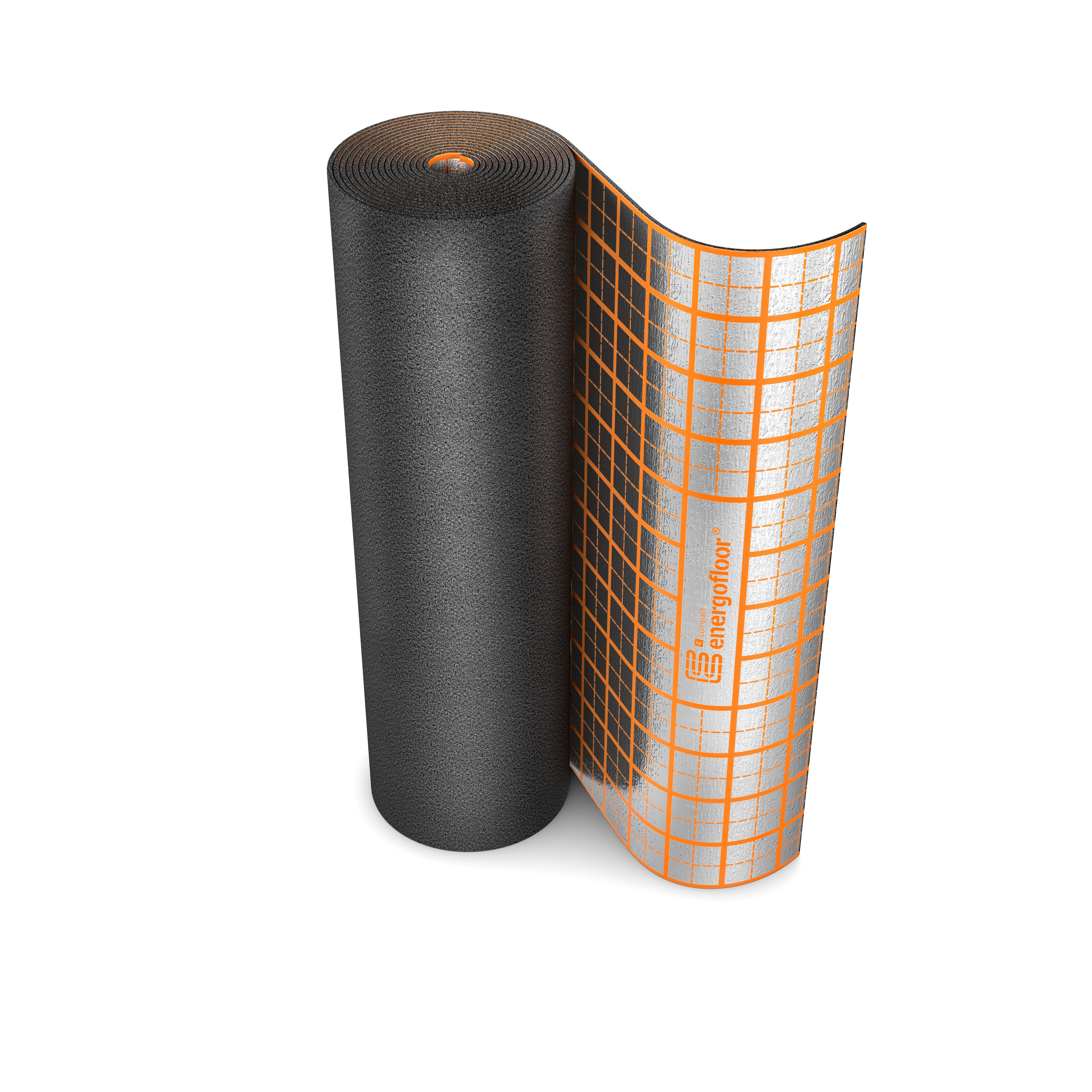

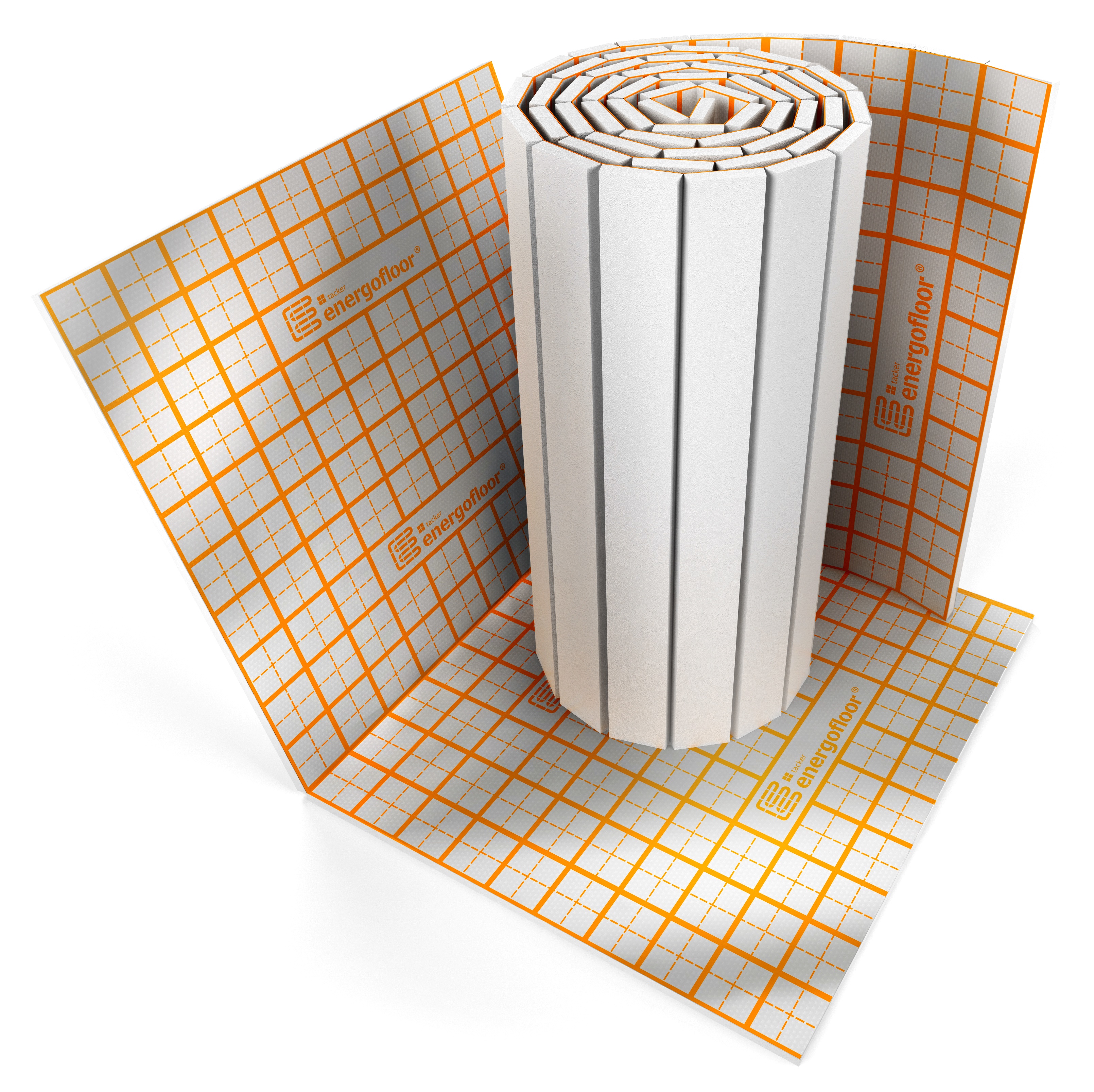

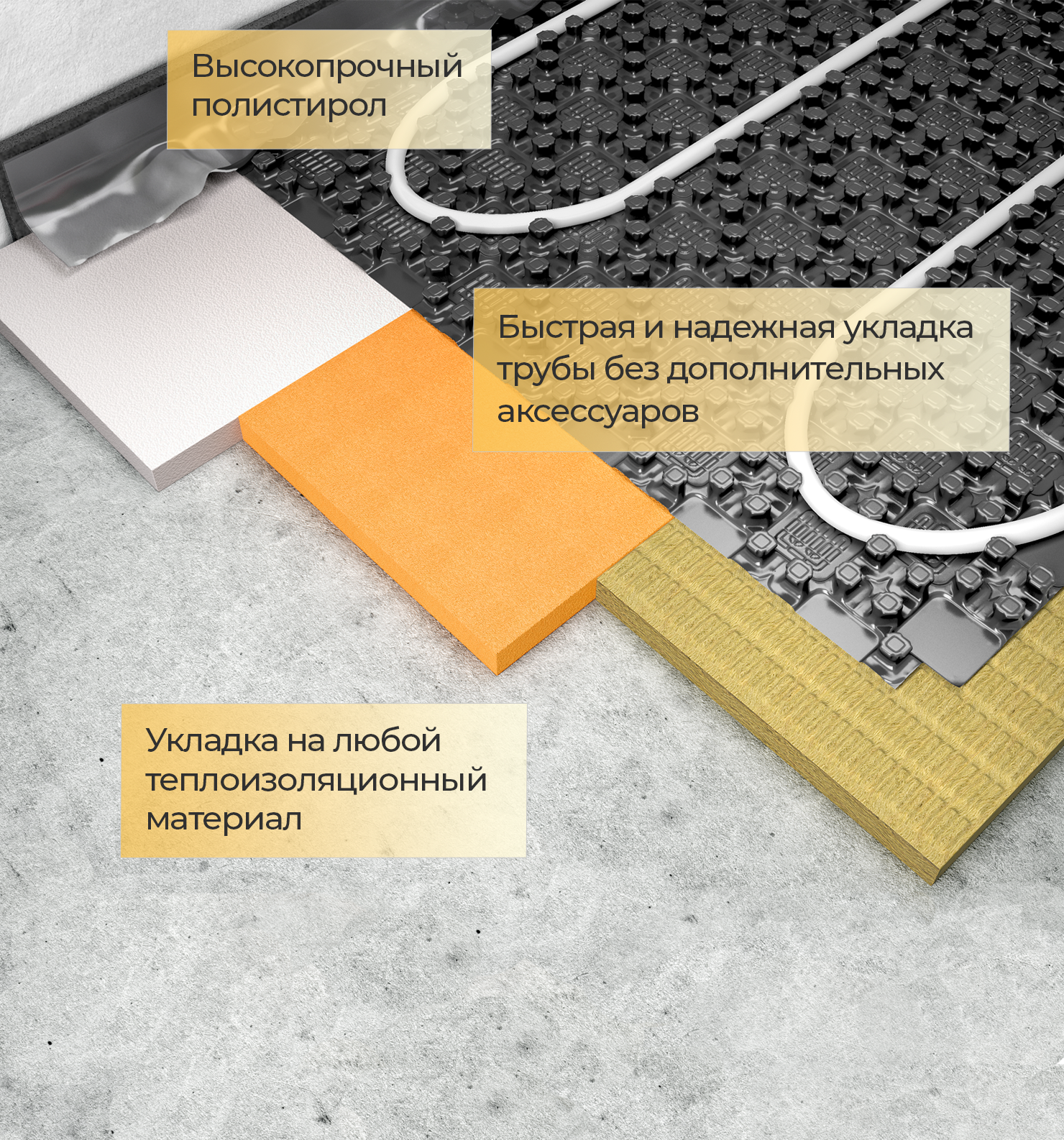

STO 59705109-005-2013 «Heat insulation for the water systems of heating, which are built in floor surfaces with application of products from Energofloor® expanded polystyrene. Engineering and installation»Details

One of the main advantages of this standard is that in it in Russia rationing on thermal resistance for the insulation materials applied in floor heating systems is introduced for the first time. And these norms are harmonized with requirements of the European standards EN 1264-4 and DIN 4108-10.

At the same time, STO were included in structure the floor design examples with application of the products Energofloor® Pipelock and Energofloor® Tacker, considering existing rules on design of insulating, specifications, requirements of fire safety, environmental protection and modern tendencies in design of heat-insulation of the equipment and pipelines.

Hide

-

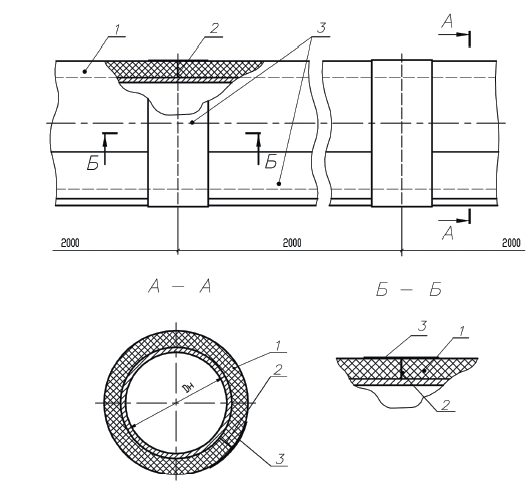

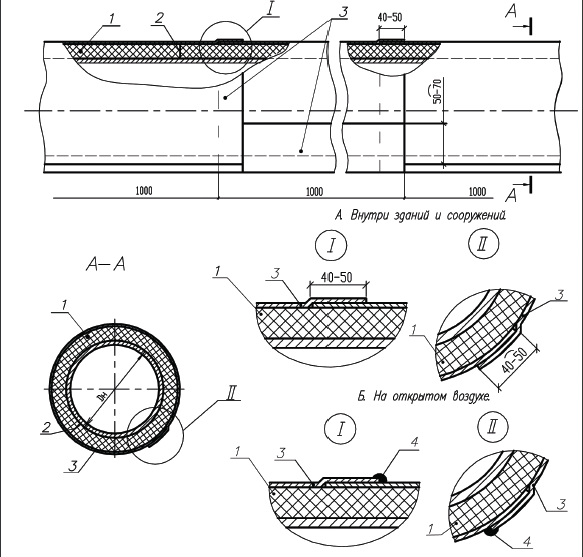

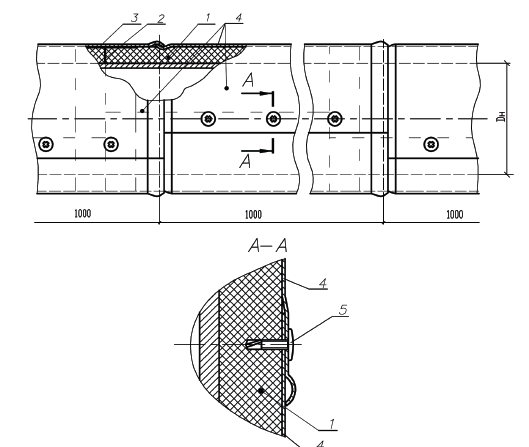

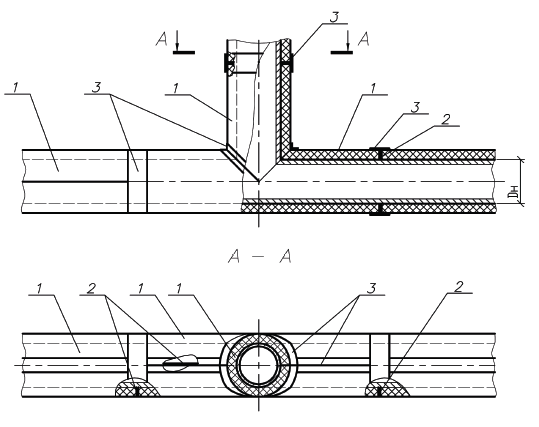

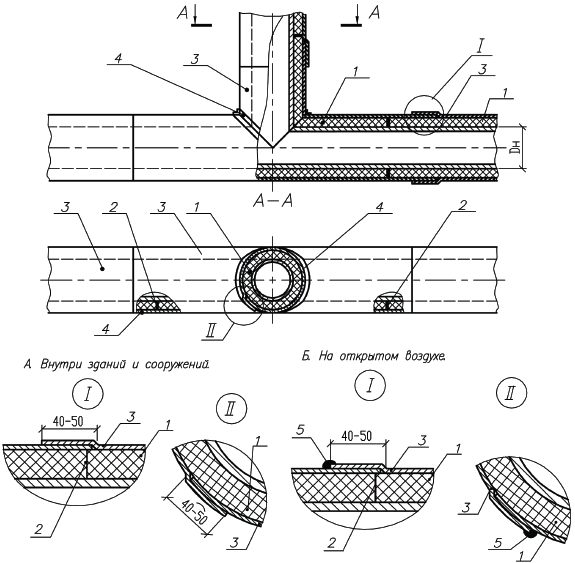

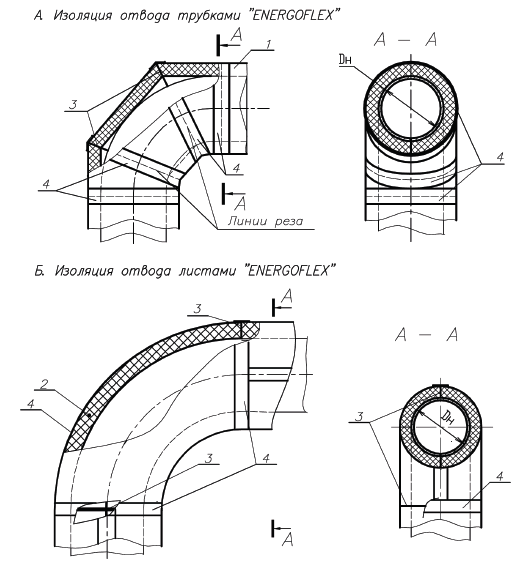

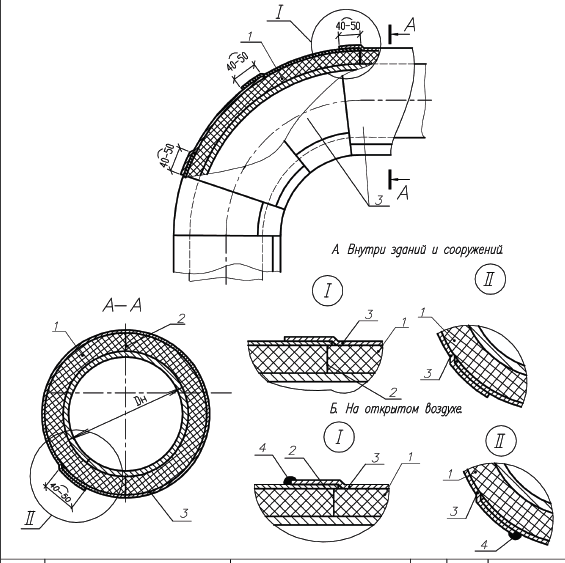

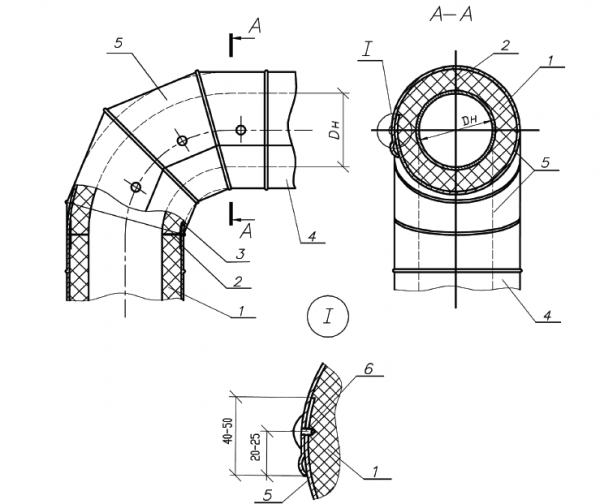

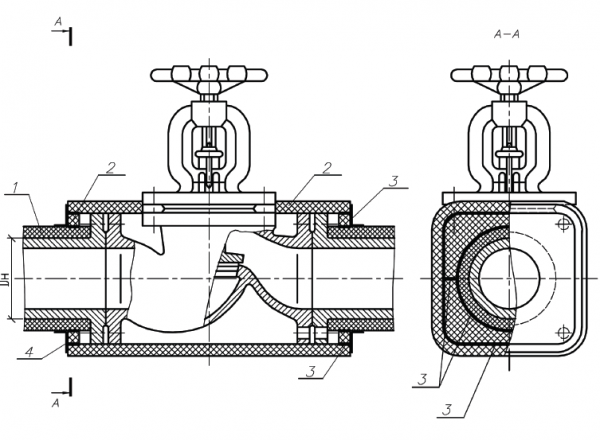

«The standard drawings album Series 5.904.9-78.08 «Heat insulation of the equipment and pipelines with the use of Energoflex® products»Details

In October, 2008, a complete set of assembly drawings series 5.904.9-78.08 for standard insulation constructions «Insulation of the equipment and pipelines with the use of Energoflex® products» was developed and put into operation by the Engineering company on thermal technical construction «Teploproject» in cooperation with ROLS ISOMARKET company.

This document represents an assembly drawings album for insulation constructions made of polyethylene foam Energoflex® for engineering systems, ventilation and air-conditioning systems, technological systems located in premises in the open air with the insulated surface temperature from − 40 °С up to + 95 °С, namely:

- pipelines,

- bends,

- tees,

- swages,

- round and rectangular air ducts,

- flanged joints and fittings,

- tanks,

- transition pieces through building constructions.

The album is designed in accordance with SPDS requirements (System of Design Documentation for Construction), SP 61.13330.2012 «Insulation of equipment and pipelines» and STO 59705183-001-2007 «Constructions of insulation with the use of Energoflex® insulating polyethylene foam products. Engineering and installation». The application of insulating materials Energoflex® both without a covering layer, and with Energopack® and Energopack® ТК covers is considered in the document.

The album of standard drawings is the first document of this kind in Russia created for the effective application of modern insulating materials. Its application considerably simplifies the work for design organizations employees. Having this document a specialist needs only to choose the necessary drawing and to specify its number by the preparation of the design documentation according to GOST 21.405-93 requirements «System of building design documents. Rules of carrying out of working documents of heat insulation of equipment and pipelines». In other words, the document allows to reduce time for the preparation of the design documentation, thus maintaining high accuracy of calculations and observance of the requirements to the engineering design documentation.

Hide

-

STO 59705183-001-2007 «Constructions of insulation for the equipment and pipelines with the use of Energoflex® insulating products. Engineering and installation»Details

In 2007, the Engineering company on thermal technical construction «Teploproject», OJSC, GUP MNIITEP and a group of specialists of ROLS ISOMARKET company developed the first Russian regulatory document for the engineering of insulation with the use of insulating products from polyethylene foam of the famous Russian brand Energoflex® – STO 59705183-001-2007 «Constructions of heat insulation for the equipment and pipelines with the use of Energoflex® insulating products. Engineering and installation». This standard became the first official document in Russia establishing the requirements to the engineering and installation insulation constructions from polyethylene foam products and considering the specific character of materials of this type. The document has passed the examination in the Open Joint-stock company «Center for Methodology, Normalization and Standardization in Civil Engineering» (TsNS, OJSC) and is registered by the Technical Committee TK 465 «Building» that confirms its conformity to the existing regulatory system of the Russian Federation.

The standard contains:- requirements to insulation constructions, Energoflex® insulating products, Energopack® covering materials and accessories for the installation Energoflex® and Energopack®;

- requirements to the engineering and calculation methods for insulation constructions with examples of the most widespread application cases;

- requirements to the insulation works with the use of Energoflex® materials.

All requirements are structured by separate sections according to the purpose of an insulated engineering system, for each of which unequivocal designing rules are established. Along with this, the transition from a tough rating of thermal losses to the calculation of a power efficient thickness of a insulating layer is established in the Standard for the first time. The calculation procedure allows to project an insulation construction taking into account operating life, costs of thermal energy, the price of insulating and covering materials (including installation accessories), as well as expenses for the performance of insulation works and a payback of insulation constructions for each specific case. At the same time, tables with effective thicknesses of insulating layers from Energoflex® material are given in the document for the most widespread cases of application.

Hide

-

For specialistsThe quality management system of the company conforms to the international standard GOST R ISO 9001 – 2015 (ISO 9001:2015).Details

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- Revit 2016 project in «.rvt» format with insulation trademarks;

- insulation models in «.ifc» format;

- instructions for working with models.

- requirements to technology of performance of insulating works;

- requirements to control of performance of work;

- requirements to formation of reporting and technical documentation;

- requirements to quality of performance of work.

The use of digital BIM-models allows you to visualize designs and more accurately reflect all the nuances of insulation installation, unlike conventional 2D-drawings.

CAD-systems are used to create and work with such models, allowing you to comprehensively solve design, construction and operation problems.

Videos, that teach you how to work with BIM-models of our insulation for Autodesk Revit, can be viewed on the YouTube channel ROLS ISOMARKET

QUALITY IS DETERMINED BY GOST!

The detailed recommendations given in the manual are based on a long-term practical experience. They will allow to mount various types of insulation constructions quickly and in a good manner as well as to guarantee the reliability of their subsequent operation.

Energomax®, Energoflex® BIM-models

Files in Library:

These families of BIM-models of insulation are developed for versions of Revit 2019 and above, Dynamo 2.0 and above.

The specification contains:

New BIM-models will allow you to:

The catalogue is designed for the experts, who are involved into the engineering and deliveries of insulation materials.

The catalog contains the detailed information on all products offered by ROLS ISOMARKET company. The catalog's task is to facilitate the operation with Energomax®, Energoflex®, Energocell® HT, Energofloor® insulation, covering materials Energopack® and branded accessoriesas Energopro® much as possible.

ROLS ISOMARKET company has carried out certification of theinsulating materials Energoflex® on compliance of GOST R 56729-2015 (EN 14313:2009) «Insulating products from a polyethylene foam factory production, applied to the engineering equipment of buildings and plants. General specifications».

It is possible to study the full text of GOST R 56729-2015 (EN 14313:2009) on the website of Federal Agency for Technical Regulation and Metrology ROSSTANDARTО

Training center

Do you implement insulation from the ROLS ISOMARKET company, but want to know about it more to increase sales? Or you project modern engineering systems, using insulating materials, which are offered by ROLS ISOMARKET? Or, perhaps, you professionally are engaged in mounting of engineering networks, but you have questions, connected with installation of insulation?

Now in the Training Center of ROLS ISOMARKET answers to these and many other questions can absolutely free of charge be received during the consultation with our experts.

Our specialists not only willingly will share the knowledge with sellers, designers and assemblers, but also will help to work all subtleties of installation of different types of insulating materials at stands-models.

For those, who cannot personally visit our Center, a remote consulting format is provided – online seminars (webinars).

To learn about time of holding consultations and also to be registered as the participant, it is enough to pass to the website of the Training Center of ROLS ISOMARKET www.energoflex.pro. Fill a form of the participant, and our technicians will contact you.

We will be glad to see everyone at:

27, building 2, Vyatskaya str., Moscow.

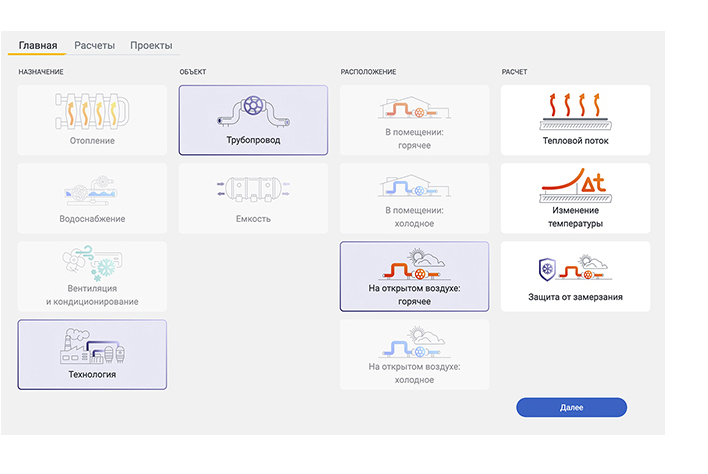

Calculation software

Specialists of the ROLS ISOMARKET company developed the new software ROLS PROJECT 2.

The new version of software has a number of advantages:

- location of the software – website. This greatly simplifies access to the service, since there is no need to download third-party software and bypass corporate restrictions on its installation;

- the program allows you to calculate of insulation structures, based on the entire range of products manufactured by ROLS ISOMARKET, including 3rd generation of insulation Energomax®.

- integration of the software with the 1C platform of ROLS ISOMARKET ensures the relevance of the nomenclature and cost of all components of the calculated insulation structure.

- ROLS PROJECT 2 contains fully automated calculation of insulation thickness for heating and heat supply systems by rated heat flow, which eliminates the need to refer to reference tables SP 61.13330.

The software is intended for calculation of thickness of insulating constructions on the basis of the products Energomax®, Energoflex®, Energocell® HT and the covering materials Energopack® for heating, water supply, ventilation, conditioning and process equipment. The program can be used for drawing up the work documentation, according to GOST 21.405-93 «Rule of execution of the work documentation of insulation of the equipment and pipelines».

NIU MGSU recommends Energoflex®

The author's team of scientific employees of NIS MGSU – the head National Research University of the Ministry of Construction of the Russia – was developed recommendations on the use of products made of foamed polyethylene Energoflex® Super for insulation of pipelines. The document focuses on the huge experience, gained by the authors during the creation of SP 61.13330.2012 «Insulation of equipment and pipelines», as well as taking into account modern trends in design. The document contains requirements for insulation products and structures, methods of calculating the thickness of insulation and, most importantly, tables with calculated thickness values of Energoflex® Super products, intended for heating systems and meeting the requirements of SP 61.13330.2012 with regard to the standard density of heat flux. The recommendations, developed by NIU MGSU, significantly facilitate the work of specialists, who are engaged in thermal engineering calculations or design of heating networks inside buildings and simplify the examination of design documentation. With its unique technical capabilities and vast technological experience, ROLS ISOMARKET is the only company, that can produce insulation tubes, made of foamed polyethylene, with wall thickness of 32 and 40 mm, meeting the requirements of SP 61.13330.2012 «Insulation of equipment and pipelines».

Insulation selection table

It is recommended to use a special summary table for convenience of Energomax®, Energoflex® and Energocell® HT insulation selection by diameter for different types of pipes. The table is advisory in nature. When using it, it is recommended to take into account the tolerances of pipe manufacturers for external diameter and their ratio with tolerances for internal diameter of insulation. Tolerances for internal diameter of insulation are given in table Limit deviations of the sizes.

| Insulation inner diameter, mm | Steel pipes | Copper pipes | |||||

| Pipes for gas and water conveyance | Longitudinal welded pipes | For refrigerating engineering and air-conditioning | Sanitaryware | ||||

| Inches | Inches | ||||||

| 6 | 1/4 | 6,35 | 6 | ||||

| 8 | 5/16 | 7,93 | 8 | ||||

| 10 | 10/10,2 | 3/8 | 9,53 | 10 | |||

| 12 | 12 | 1/2 | 12,70 | 12 | |||

| 15 | 1/4 | 8 | 13,5 | 15/16 | 5/8 | 15,88 | 15 |

| 18 | 3/8 | 10 | 17 | 18 | 3/4 | 19,05 | 18 |

| 22 | 1/2 | 15 | 21,3 | 21,3/22 | 7/8 | 22,22 | 22 |

| 25 | 25 | ||||||

| 28 | 3/4 | 20 | 26,8 | 28 | 1 1/8 | 28,57 | 28 |

| 30 | 30 | ||||||

| 35 | 1 | 25 | 33,5 | 33,7/35 | 1 3/8 | 34,92 | 35 |

| 42 | 1 1/4 | 32 | 42,3 | 42 | 15/8 | 41,27 | 42 |

| 45 | 44,5/45 | ||||||

| 48 | 1 1/2 | 40 | 48 | 48/48,3 | |||

| 54 | 54 | 2 1/8 | 53,98 | 54 | |||

| 60 | 2 | 50 | 60 | 57/60 | |||

| 64 | 63,5 | 64 | |||||

| 70 | 70 | 2 5/8 | 66,66 | ||||

| 76 | 2 1/2 | 65 | 75,5 | 76 | 76,1 | ||

| 89 | 3 | 80 | 88,5 | 89 | 88,9 | ||

| 110 | 108 | 108 | |||||

| 114 | 4 | 100 | 114 | 114 | |||

| 133 | 133 | 133 | |||||

| 140* | 5 | 125 | 140 | 140 | |||

| 160 | 159 | 159 | |||||

| Outer diameter, mm | Polypropylene pressure pipes PP | Metal-reinforced plastic pipes | Cross linked polyethylene pipes PE-X | Sanitary drain pipes made of polypropylene and PVC PP/PVC | |

| PP | PP-R armoured | ||||

| 15 | 14 | 14 | |||

| 18 | 16/17 | 16/17 | |||

| 22 | 20 | 22,3 | 18/20 | 18/20 | |

| 25 | 25 | ||||

| 28 | 27,3 | 25/26 | 25 | ||

| 35 | 32 | 34,3 | 32 | 32 | |

| 42 | 40 | 42,7 | 40 | 40 | |

| 54 | 50 | 53,3 | 50 | 50 | 50 |

| 64 | 63 | 63 | 63 | ||

| 76 | 75 | 78,3 | 75 | 75 | |

| 89 | 90 | ||||

| 110 | 110 | 110 | |||

* It is recommended, that tubes Energomax® and Energoflex® with an internal diameter of 160 mm be used for insulation of 140 mm pipes, removing excess material along the entire length before installation.

Energopack® bends selection table

| Outer Ø of pipeline, mm, no more, than |

Thickness of insulation layer, mm | ||||||||

| Standart size of bend | |||||||||

| 9-10 | Article | 13-15 | Article | 20 | Article | ||||

| 32 | 80(R30) | EPKO08005030ST | 90(R30) | EPKO09005030ST | |||||

| 38 | 80(R30) | EPKO08005030ST | 90(R30) | EPKO09005030ST | 110(R30) | EPKO11005030ST | |||

| 45 | 80(R30) | EPKO08005030ST | 90(R30) | EPKO09005030ST | 110(R30) | EPKO11005030ST | |||

| 57 | 90(R35) | EPKO09005035ST | 100(R30) | EPKO10005030ST | 120(R30) | EPKO12005030ST | |||

| 76 | 100(R50) | EPKO10005050ST | 120(R45) | EPKO12005045ST | 130(R40) | EPKO13005040ST | |||

| 89 | 120(R65) | EPKO12005065ST | 130(R60) | EPKO13005060ST | 150(R55) | EPKO15005055ST | |||

| 108 | 140(R85) | EPKO14005085ST | 150(R80) | EPKO15005080ST | 170(R75) | EPKO17005075ST | |||

| 114 | 150(R80) | EPKO15005080ST | 160(R75) | EPKO16005075ST | 170(R70) | EPKO17005070ST | |||

| 133 | 170(R110) | EPKO17005110ST | 180(R105) | EPKO18005105ST | 190(R100) | EPKO19005100ST | |||

| 159 | 200(R135) | EPKO20005135ST | 210(R130) | EPKO21005130ST | 220(R125) | EPKO22005125ST | |||

| 168 | 210(R130) | EPKO21005130ST | 210(R125) | EPKO21005125ST | 220(R120) | EPKO22005120ST | |||

| 219 | 250(R180) | EPKO25005180ST | 250(R175) | EPKO25005175ST | 270(R170) | EPKO27005170ST | |||

| 273 | 300(R225) | EPKO30005225ST | 310(R220) | EPKO31005220ST | 320(R215) | EPKO32005215ST | |||

| 325 | 350(R275) | EPKO35005275ST | |||||||

| Outer Ø of pipeline, mm, no more, than |

Thickness of insulation layer, mm | ||||||||

| Standart size of bend | |||||||||

| 23-25 | Article | 30 | Article | 33-35 | Article | ||||

| 32 | 100(R30) | EPKO10005030ST | 110(R30) | EPKO11005030ST | 120(R30) | EPKO12005030ST | |||

| 38 | 110(R30) | EPKO11005030ST | 120(R30) | EPKO12005030ST | 120(R30) | EPKO12005030ST | |||

| 45 | 110(R30) | EPKO11005030ST | 120(R30) | EPKO12005030ST | 130(R30) | EPKO13005030ST | |||

| 57 | 120(R30) | EPKO12005030ST | 130(R30) | EPKO13005030ST | 140(R30) | EPKO14005030ST | |||

| 76 | 130(R35) | EPKO13005035ST | 140(R30) | EPKO14005030ST | 150(R30) | EPKO15005030ST | |||

| 89 | 140(R50) | EPKO14005050ST | 150(R45) | EPKO15005045ST | 160(R40) | EPKO16005040ST | |||

| 108 | 170(R70) | EPKO17005070ST | 170(R65) | EPKO17005065ST | 180(R60) | EPKO18005060ST | |||

| 114 | 170(R65) | EPKO17005065ST | 180(R60) | EPKO18005060ST | 190(R55) | EPKO19005055ST | |||

| 133 | 190(R95) | EPKO19005095ST | 200(R90) | EPKO20005090ST | 210(R85) | EPKO21005085ST | |||

| 159 | 220(R120) | EPKO22005120ST | 220(R115) | EPKO22005115ST | 230(R110) | EPKO23005110ST | |||

| 168 | 220(R115) | EPKO22005115ST | 230(R110) | EPKO23005110ST | 240(R105) | EPKO24005105ST | |||

| 219 | 270(R165) | EPKO27005165ST | 280(R160) | EPKO28005160ST | 290(R155) | EPKO29005155ST | |||

| 273 | 330(R210) | EPKO33005210ST | 340(R205) | EPKO34005205ST | 350(R200) | EPKO35005200ST | |||

| Outer Ø of pipeline, mm, no more, than |

Thickness of insulation layer, mm | ||||||||

| Standart size of bend | |||||||||

| 40 | Article | 45 | Article | 50 | Article | ||||

| 32 | 140(R30) | EPKO14005030ST | 150(R30) | EPKO15005030ST | 160(R30) | EPKO16005030ST | |||

| 38 | 130(R30) | EPKO13005030ST | 140(R30) | EPKO14005030ST | 150(R30) | EPKO15005030ST | |||

| 45 | 140(R30) | EPKO14005030ST | 160(R30) | EPKO16005030ST | 170(R30) | EPKO17005030ST | |||

| 57 | 150(R30) | EPKO15005030ST | 160(R30) | EPKO16005030ST | 180(R30) | EPKO18005030ST | |||

| 76 | 160(R30) | EPKO16005030ST | 180(R30) | EPKO18005030ST | 190(R30) | EPKO19005030ST | |||

| 89 | 170(R35) | EPKO17005035ST | 180(R30) | EPKO18005030ST | 200(R30) | EPKO20005030ST | |||

| 108 | 190(R55) | EPKO19005055ST | 200(R50) | EPKO20005050ST | 210(R45) | EPKO21005045ST | |||

| 114 | 200(R50) | EPKO20005050ST | 210(R45) | EPKO21005045ST | 220(R40) | EPKO22005040ST | |||

| 133 | 220(R80) | EPKO22005080ST | 230(R75) | EPKO23005075ST | 240(R70) | EPKO24005070ST | |||

| 159 | 240(R105) | EPKO24005105ST | 250(R100) | EPKO25005100ST | 260(R95) | EPKO26005095ST | |||

| 168 | 250(R100) | EPKO25005100ST | 260(R95) | EPKO26005095ST | 270(R90) | EPKO27005090ST | |||

| 219 | 300(R150) | EPKO30005150ST | 310(R145) | EPKO31005145ST | 320(R140) | EPKO32005140ST | |||

Limit deviations of the sizes

Limit deviations of the sizes Energomax®, Energoflex®, Energocell® HT

| Trademark | Product type | Length | Width | Thickness, mm | Normative document | |

| Declared | Limit deviation | |||||

| Energomax®, Energoflex® | Tubes |

- 1,5% + 2,5% |

- |

dD ≤ 6 6 < dD ≤ 10 10 < dD ≤ 15 15 < dD ≤ 30 dD > 30 |

± 1,0 ± 1,5 ± 2,0 ± 2,5 ± 4,0 |

STO 59705109-011-2019 (Energomax®) GOST R 56729-2015 (Energoflex®) |

| Sheets (rolls) | ± 1,5% | ± 1,0% |

15 < dD ≤ 30 dD > 30 |

± 2,5 ± 3,5 |

||

| Tapes | ± 1,5% | ± 2,0% | - | ± 0,5 | ||

| Energocell® HT | Tubes | ± 1,5 % | - |

dD ≤ 8 8 < dD ≤ 18 18 < dD ≤ 31 dD > 31 |

± 1,0 ± 1,5 ± 2,5 ± 3,0 |

STO 59705109-006−2014 |

| Sheets (rolls) |

+5,0 % -1,5 % |

± 2,0% |

dD ≤ 6 6 < dD ≤ 19 dD > 19 |

± 1,0 ± 1,5 ± 2,0 |

||

| Tapes |

+5,0 % -1,5 % |

± 2,0% | dD = 3 |

- 0,1 +1,5 |

||

Limit deviations of inner diameter of tubes Energomax®, Energoflex®, Energocell® HT

| Trademark | Inner diameter, mm | Normative document | ||

| Di,D ≤ 35 | 35 < Di,D ≤100 | Di,D > 100 | ||

| Energomax® | From +1 toо +4 | From +2 to +6 | From +3 to +8 | STO 59705109-011-2019 |

| Energoflex® | From +1 to +4 | From +2 to +6 | From +3 to +8 | GOST R 56729-2015 |

| Energocell® HT | From +1 to +4 | From +1 to +6 | STO 59705109-006−2014 | |

Energofloor® BIM-models

Files in Library:

In March, 2013 No. 2.12.69-2012 NOSTROY standard №2.12.69-2012 « Insulating works for internal pipelines of buildings and constructions» came out.

This standard conforms to requirements of federal laws « On technical regulation» (No. 184-FZ) » (No. 184-FZ) and « Technical regulations about safety of buildings and constructions » (No. 384-FZ), and also requirements of the town-planning code of the Russian Federation regarding article 55.13. Besides, in the standard current trends of development of the construction industry, and also knowledge and practical practices of leading companies of branch are considered.

The standard contains a number of requirements:

Regulatory documentation is provided free of charge.

Write to us e-mail, which regulatory documents are of interest to you.